What Makes JYF Machinery’s Shredder Blades Stand Out

JYF Machinery has grown as a reliable producer of shredder blades and wear parts of high performance that are used in industrial shredding processes. Having more than twenty years of expertise in precision engineering and material science, the company is concentrating on the delivery of cutting solutions of a durable nature that can be operated successfully in harsh operating environments. What is unique about the industrial shredder blades of JYF Machinery is the combination of the latest production methods, the use of low-quality materials, and the knowledge of real-life problems related to shredding in the recycling business, forestry, agriculture, and garbage disposal.

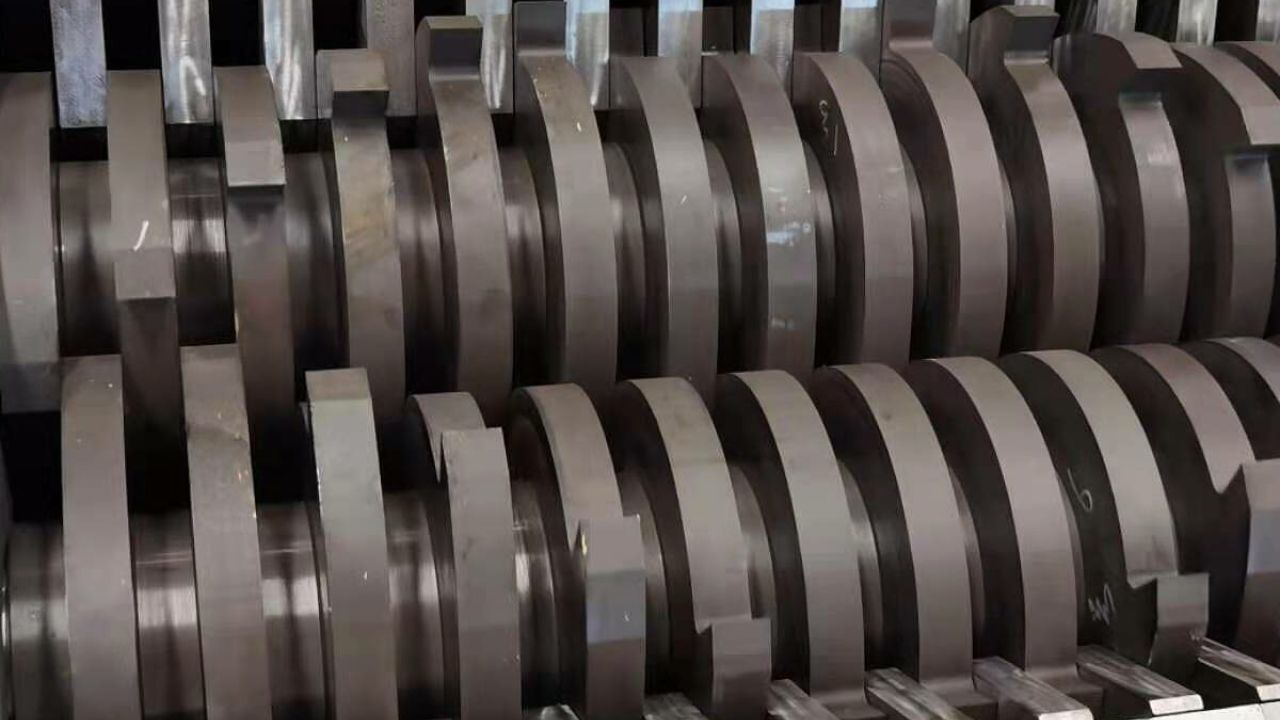

Advanced Heat Treatment and Forging Processes

JYF Machinery also puts much stress on heat treatment and forging because they directly affect the performance of the blade and its service life. The shredder blades are also treated thermally to achieve uniform hardness of the cutting surface and offer core toughness. This balance reduces the possibility of cracking or premature breakdown during heavy-duty shredding. Forging process also increases the internal grain structure, boosts impact resistance and ability to bear a load. These are technical benefits that enable JYF shredder blades to work reliably in low-speed, high-torque shredders as well as high-output industrial systems.

Precision Engineering for Consistent Cutting Performance

Another important aspect that makes the shredder blades of JYF Machinery different is precision machining. Close dimensional clearances provide proper blade fit, alignment and easy movement throughout operation. Such accuracy minimizes shaking, uneven wear and unjustified stress to shredder shafts and frames. Shredding efficiency is also enhanced by the consistent cutting geometry, which leads to the same reduction of material size and a smoother downstream processing. As a result of emphasizing precision engineering, JYF will assist customers in increasing their throughput with a constant machine performance.

Wide Range of Blade Designs for Diverse Applications

JYF Machinery has a wide variety of shredder blade types that are suitable for a wide range of materials and applications. The single and double-blades have been combined with hook, shear, needle, and dual-shaft designs, each blade being designed to suit certain shredding requirements. Such flexibility enables the operators to use the most appropriate blend of the blade to the materials, which include plastic films, rubber, metals, wood, textiles and municipal solid waste. The blade designs are specialized and are designed to be the most efficient in cutting, as well as minimizing unwarranted wear in the process.

Customization Capabilities to Meet Specific Needs

The other feature that sets JYF machinery apart is the fact that it offers personalized solutions with regard to shredder blades. The company collaborates hand in hand with customers to design the dimensions of the blades, materials, levels of hardness and profiles according to personal equipment models and the objectives of the processing. The customization will guarantee its ability to work with a wide range of industrial shredders and grinders, so that clients can maximize performance and achieve longer life times of the components. This consumer-driven strategy enables JYF to solve special shredding problems that regular blades might not solve adequately.

Proven Reliability Across Multiple Industries

The shredder blades of JYF Machinery are common in the recycling industry, forestry industry, agriculture, milling of roads, foundation drilling, and coal mining. The efficiency of the engineering and quality control standards of the company is proven by their successful use in the harsh working conditions. JYF provides efficient processing of waste and recovery of materials in the world through supplying blades that are resistant to wear, efficient in cutting, and with low downtime.

Commitment to Quality and Long-Term Performance

The initial element of the success of JYF Machinery is focused on high quality and long-term results. Since the choice of material for the final inspection, every shredder blade is made under a stringent quality control system. Such commitment means that customers will be supplied with reliable wear parts that will secure the investment in equipment and enhance the overall productivity as well. JYF Machinery has been able to maintain a high standard in the market of industrial shredder blades through constant innovation and technical perfection.

Conclusion

The shredder blades of JYF Machinery can be characterized by a complex of the best materials, a high level of shredder engineering and the considerate customization that allows achieving high durability and cutting efficacy. With the application of the high-quality alloy steel, which is refined through the process of forging, heat treatment, and precision machining, these blades are capable of giving the same efficiency when subjected to the most demanding industrial tasks. A multitude of different designs and the opportunity to customize solutions to individual applications make operators in the recycling, forestry, agriculture and other industries able to optimize productivity and reduce downtimes. Having a record of reliability and a firm belief in quality, JYF Machinery has been offering shredder blades that not only meet but surpassing the strict requirements of material processing of the modern era.